À propos de LIL

Cone crusher basics in 4 minutes - rockprocessing.sandvik

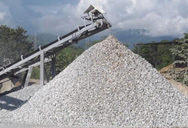

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive.

Voir plus

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Cone crushers are capable of crushing all types of medium to hard mineral rocks and stones. It also offers many advantages over other crusher designs, such as low energy

Voir plus

4 Types of Cone Crushers: What Are They and How to Select

2023.4.28 The cone crusher is a popular rock crusher in mining operations, aggregate production, and recycling applications. Many users use it for size reduction

Voir plus

Sandvik Cone Crushers - SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system,

Voir plus

Cone Crusher SpringerLink

2023.5.3 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of

Voir plus

SANDVIK CS550 CONE CRUSHER - Sandvik Mining and

2019.3.13 CONE CRUSHER Sandvik CS550 is the latest high capacity cone crusher that gives you the best operational and cost performance. It is a tough, uncompromising

Voir plus

Sandvik CS660 Cone Crusher For High Capacity Applications

Sandvik CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant

Voir plus

Improving the Efficiency of Cone Crushers in the Mining

2 天之前 Ore preparation plays a significant role in determining the final technical and economic performance of an enterprise in the mining industry. Cone crushers are the

Voir plus

Our Range of Trio® Cone Crushers Weir

Trio® cone crushers are designed particularly for secondary crushing as well as other tertiary and quaternary applications. These crushers work best in dry, well-graded and

Voir plus

A Comprehensive Guide to Cone Crusher Types

2023.2.15 Mobile cone crushers are typically used in secondary and tertiary crushing stages in mining, quarrying, and recycling applications. The mobile cone crusher is designed to be easily transported between sites

Voir plus

en/121/crusher cone information.md at main dinglei2022/en

Find and fix vulnerabilities Codespaces

Voir plus

Cone Crusher Diagram: Simplified Guide - JXSC

2024.3.19 Lower capacity compared to hydraulic cone crushers; suitable for consistent feed materials: Feed Size: Can handle larger feed sizes, typically up to 300-400 mm: Feed size is generally limited to 200-300 mm: Product Size: Can produce finer products due to precise adjustment capabilities; product size can range from 6-75 mm:

Voir plus

How Does A Cone Crusher Work: Understanding The

2023.7.31 The cone crusher has a high reduction ratio, ensuring efficient material crushing. Discharge: This is the final stage of the crushing process. When the material is crushed into the preferred size, it exits the cone crusher through an opening at the bottom. The entrance is located between the mantle and the bowl liner.

Voir plus

Nordberg® HP Series™ cone crushers - Metso

Nordberg® HP™ crushers produce finer products by limiting crushing stages, which lowers your investment cost and saves energy. This is achieved through a combination of optimized speed, large throw, crushing chamber design and increased crushing force. The efficient crushing action of the best power utilization per cone diameter.

Voir plus

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame , and tramp release mechanism (mechanically or hydraulically actuated).

Voir plus

How Does a Cone Crusher Work and What is It? - JXSC

2024.3.15 Cone crushers are really important in processing materials across different industries. Knowing how a cone crusher functions, what parts it has, and how to use it well can make a big difference in how efficient your operations are. As technology and design keep getting better, modern cone crushers are more efficient, safer, and simpler to take ...

Voir plus

4 Types of Cone Crushers: What Are They and How to Select

2023.4.28 Multi-cylinder hydraulic cone crusher. Multi-cylinder hydraulic cone crusher is the latest addition to the cone crusher family. It has a high capacity and the highest crushing force of any cone crusher of similar size. Besides, it has a good shaping effect. Therefore, it is ideal for medium crushing, fine crushing, and even superfine crushing ...

Voir plus

Sandvik CS660 Cone Crusher For High Capacity Applications

Stationary cone crushers 400-600 series. CS660 Nominal capacity 314 - 908 mtph (346 - 1,000 stph) Max. feed size 622.0 mm (24.5 in.) Motor power 315 kW (422 hp) Sandvik CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant ...

Voir plus

Raptor® Cone Crushers for Mining and Aggregate

2023.12.19 Raptor® cone crushers. RAPTOR® 250. The R250 is our smallest and . lightest weight cone crusher. Its low-profile design makes it a perfect fit for a portable and mobile chassis. RAPTOR® 450. Our R450 model is the . largest of our crushers that . do not require a backliner. It processes more usable and saleable aggregate per ton than ...

Voir plus

Nordberg® HP6™ cone crusher - Metso

Less downtime, more confidence. Nordberg® HP6™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

Voir plus

Patriot® Cone Crusher Secondary or Tertiary

4 天之前 Superior’s Patriot Cone Crusher is a durable American-made rock crusher that is highly productive and sets industry standard. The Patriot Cone Crusher is a reliable and valuable choice for secondary or tertiary

Voir plus

Cone Crushers – Jacob Bethel Corporation

2020.7.21 JBC Bulawayo, offers a range of cone crushers suitable for Secondary and Tertiary crushing. \Our Cones feature: Cam Lever Action. Large Feed Opening. \Hydraulic Relief Clamping. Anti-spin Mechanism. Hydraulic Adjust and Opening. Reduced Wear Liner replacement time.

Voir plus

Sandvik CS420 Cone Crusher For Achieving High

Max. feed size. 267.0 mm (10.5 in.) Motor power. 90 kW (121 hp) Sandvik CS420 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This equipment is suitable for a high-capacity secondary crushing application.

Voir plus

Cone Crushers - Sanland Equipment

2024.7.14 Static Cone Crushers - Sanland Equipment Symons. Dipping into a legacy that has stood the test of time, the Symons static cone crusher offers an unsurpassed crushing experience, now enriched with modern enhancements. Central to its design is the Hydraulic tramp clearance – a feature that ensures obstruction-free operation by

Voir plus

CH890i - SRP

Stationary cone crushers 800i-series. CH890i Nominal capacity 275 - 1,837 mtph (303 - 2,025 stph) Max. feed size 428 mm (17 in.) Motor power 750 kW (1,000 hp) No of chambers 4 Sandvik CH890i and is a technologically advanced, high-capacity cone crushers designed for crushing applications in mines or large sized quarries. ...

Voir plus

GitHub

sbm zibo short head cone crusherzibo hammer crusher price availablebursaries.co Zibo Crusher Price Jaw Crusher Parts Cone Crusher cone crusherzircon sand zibo datong crusherget

Voir plus

Astec Kodiak® Cone Crushers - Astec

2024.7.15 A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers on-the-fly adjustability for easy operation. 7:42.

Voir plus

Crushing Equipment, Cone Crushers, Gyratory Crushers

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it ...

Voir plus

Cone Crushers

The unique crushing action of SH Series cone crushers creates a higher value for your product by providing a more consistent gradation and a superior product shape. The ability to operate at a fixed mechanical setting-instead of the head floating on a column of hydraulic oil-creates less setting drift and provides more stability throughout the ...

Voir plus

Jaw Crusher vs. Cone Crusher: Which One is Right for You?

2023.10.20 However, cone crushers also have the following disadvantages: 1. The rotating body is higher, generally 2-3 times higher than the jaw crusher, so the construction cost of the plant is relatively high; 2. The weight of the machine is large. It is 1.7-2 times heavier than a jaw crusher with the same size of the ore opening, so the investment cost ...

Voir plus

Cone Crushers - Crushing Tigers

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

Voir plus

Cone Crushers Mobile High Productivity Terex Finlay

2024.7.11 The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides large reduction ratios and an excellent cubical shaped end product. The robust design of the plant enables it to accept an all in feed and makes it particularly suitable

Voir plus

Raptor® Cone Crusher best in class FLSmidth

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For mining applications, we recommend the R500 to the R2500, though we also offer smaller crushers that are typically used in aggregates. We designed each model using industry feedback.

Voir plus

Nordberg HP Series cone crushers – High performance

2023.1.20 19. Nordberg HP Series cone crushers 3. Proven and predictable production. HP Series cone crushers provide predictable and consistent capacity, end product size, gradation and shape, making them a safe choice for aggregates and mining processes. The crusher setting is mechanically fixed while crushing and it is secured by

Voir plus

Guide to Cone Crusher Liners — How to Choose and When

2022.2.11 Overview of Cone Crusher Liner. Cone crusher liner features several components, such as bowl liner wedges, linebacker, locking bolt liner, torch rings, locking bolts, and feed plates.

Voir plus

Nordberg® MP Series™ cone crushers - Metso

Nordberg® MP™ crushers bring cone crusher performance to a new level. They provide the highest crushing power for any cone crusher of similar size. Advanced crushing dynamics leads to more work per cycle. The MP™ crushers increase the power draw resulting in an increase in capacity, and a higher power-to-production ratio and energy efficiency.

Voir plus

en/167/specs kue ken cone crusher.md at main lbsid/en

Contribute to lbsid/en development by creating an account on GitHub.

Voir plus

Cone Crusher - an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 6.8).Major suppliers of cone crushers

Voir plus

>> Next:Fournisseurs De Concasseurs De La Sable De Ciment Contenant

Consulter en ligne

- prix des micro pulvérisateur

- impact global concasseur

- bengkel pembuatan convoyeur di medan

- procédNouvelle Caldonia et un appareil pour la réparation des bandes transporteuses

- ciment manuel d utilisation du moulin

- pierre concasseur fabricants dinde concasseur de pierre de dinde

- vendre broyeur occasion colombie

- système mesto de concassage

- bille en carbure de calcium moulin

- faire la poussière de calcaire avec vsi

- pulverizer mill fabricants concasseur et mill

- concasseur Indonésie mâchoire Indonésie vendre or

- re broyage de broyeurs a boulets

- convoyeur a bande digunakan

- fournisseur de pièces Afrique concasseur de pierre Indonésie bihar