À propos de LIL

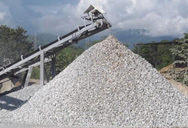

Mining Crushers AllMinings

2024.5.24 A mining crusher is a machine used to reduce large rocks into smaller pieces. Crushers are designed to handle a range of materials. It is from ores to coal and various minerals used in the mining industry. There are several types of crushers

Voir plus

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Crushers. Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary

Voir plus

Types of Crushers Explained: Everything You Need to Know

2024.4.19 Crushers are key equipment in mining, construction and aggregate industries. They break large rocks, ore, or other materials into smaller, more usable

Voir plus

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK

2019.3.13 A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future. This guide covers a few of the key points to

Voir plus

Crushing and Screening Handbook - AusIMM

2021.6.24 We at Metso’s Mining and Construction Technology hope that this book contributes to an improved understanding of quarrying operations and thus helps us all to

Voir plus

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive.

Voir plus

Crushers SKF

2024.6.12 The right solutions can help ensure crusher bearings deliver the necessary performance while avoiding premature failure. Explore our bearing, sealing, lubrication,

Voir plus

Metso introduces new crushing solution Global Mining

2024.5.21 Metso is launching the XM Series, a highly advanced premium crushing solution that combines intelligence, durability and lifetime value with a new digital

Voir plus

Rock Crushing Process in Mining - 911 Metallurgist

2015.7.18 Most crushers load the solid particles they crush as beams or short columns, but explosive shattering, whether by dynamite or by steam, loads them largely

Voir plus

Cone Crushers (Parts of a Cone Crusher)

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically

Voir plus

sbmchina/sbm vsi crusher roche entretien.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Voir plus

Hard Rock Mining Equipment Crushing Plants

3 天之前 WIDE RANGE: DOVE is the leader and powerhouse in the mining equipment manufacturing industry and over the last 50 years has produced the largest range of Semi-stationary Hard Rock Plants

Voir plus

Primary Crusher vs. Secondary Crusher: Understanding Their

2023.2.28 The function of the primary crusher is to break down the larger rocks and stones into manageable sizes, while the function of the secondary crusher is to further refine these sizes into the desired product. The secondary crusher operates by compressing the material between two surfaces, similar to the primary crusher.

Voir plus

fr/fabriqué en allemagne rocks crusher au libéria.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Voir plus

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Voir plus

What Are Jaw Crushers and How Do They Work? Oreflow

The eccentric in a double-toggle jaw crusher is found behind the swinging jaw, while the eccentric on the single-toggle is located at the top. Conclusion. Jaw crushers are essential equipments in all mining and ore industries. These machines allows mine engineers to crush and compact large pieces of hard material in a safe and efficient manner.

Voir plus

Metso introduces new crushing solution Global Mining

2024.5.21 The three of these technologies combined give the edge needed to make smarter decisions about the crusher and prevent downtime,” explained Vinicius Vilela, Vice President, Mining Crushers at Metso. “On top of this, as the first of its kind available in the mining industry, the warranty covers up to 25 years of life for the crusher ...

Voir plus

10" x 16" Jaw Crusher - Mt Baker Mining and Metals

The throughput is respectable at 5-20 tons per hour, and the crusher will take up to 9″ feed material. We supply this machine with either a 20 hp 3 phase electric motor or a 20 hp Honda gas engine. We’ve sold many of these as standalone machines, in our 10″ x 16″ Jaw Crusher Module, or incorporated into our 4-5 ton per hour Turn-Key Ore ...

Voir plus

A Comprehensive Guide to Cone Crusher Types

2023.2.15 The short head cone crusher is commonly used in the mining and aggregate industries for crushing smaller volumes of material. In addition to its various types, the Symons Cone Crusher is known for its

Voir plus

4 Types of Cone Crushers: What Are They and

2023.4.28 Multi-cylinder hydraulic cone crusher. Multi-cylinder hydraulic cone crusher is the latest addition to the cone crusher family. It has a high capacity and the highest crushing force of any cone crusher of

Voir plus

The Complete Guide to Primary Crushing,

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has

Voir plus

Minerai de fer Québec Site Web officiel Mine du Lac

2 天之前 Découvrez l'entreprise propriétaire de la mine de Lac Bloom qui prévoit extraire un minerai de fer de qualité inégalée dans les prochaines années. Ressource minière 100 % québécoise. Fermont, Québec, Canada

Voir plus

Primary Crushing: A Comprehensive Guide - JXSC

2024.2.23 Picking out the right equipment for primary crushing is a big deal because it really affects how well the whole crushing and processing setup works. For top primary crusher manufacturers, read 10 Best Crusher Manufacturers for Your Mining Project. There are a few important things to think about to make sure you’re making the best choice.

Voir plus

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

Voir plus

projet trémie d alimentation avec crible ... - Mining Quarry

2013.3.25 Silos / trémies – Budde F?rdertechnik GmbH. Trémie d'alimentation avec crible vibrant dans une installation de traitement de sols Trémie d'alimentation avec bande de dégagement dans une installation de .

Voir plus

Jaw Crushers - Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, full-enclosure guards, all integrated on a steel skid. Over-sized bearings and castings, robust construction, long-wearing cast manganese steel jaw plates. Optional steel stand. Sizes: 6”x 10” through 20” x 30″ jaw opening. Discharge size: ranges from 3/4” minus through 4 ...

Voir plus

What are the types of crushers? – Sandrock Mining

2021.5.27 1. A kind of extrusion crushing equipment, such as jaw crusher, cone crusher, etc., suitable for crushing raw materials with high wear index. The content of stone powder in the product is low, but there are many needle-like particles in the crushed material, and the suction performance is poor. 2. One is impact crushing equipment,

Voir plus

Primary Crusher Optimisation for Improved Comminution

2024.6.13 DEFINITION. The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher.

Voir plus

programme d'entretien crusher

Programme d entretien des concasseurs à double rotor. concasseur machoire entretien séparateur de tamis vibrantprogramme d entretien pour Toutes les séries de concasseurs à mâchoires béton rendement jour concasseur double rotor plan installation crible concasseur -Programme d entretien des concasseurs à double rotor .

Voir plus

Crusher Operator - Terra Mining

Crusher Operator About Us. Terra Mining are a dynamic leader in Western Australia’s mining sector, which rapidly expanding its portfolio of projects across the region. As we embark on new ventures and continue to grow, we have achieved the role as the primary mine operator at Extension Hill, situated 270km southeast of Geraldton. ...

Voir plus

Mining crushers SuperiorTM MKIII Primary Gyratory

2022.12.28 metallurgy and thousands of crusher installations around the world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability. Metso Outotec’s line of Superior™ Primary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations.

Voir plus

Jaw Crusher Parts Aftermarket Wear and Spare Parts GTEK - GTEK MINING

5 天之前 Manganese Liners for Jaw Crusher. The jaw plates and the cheek plates are the most common wear parts that need to be replaced frequently. GTEK is able to produce jaw plates with different tooth shapes and materials as per your request. Typical metallurgical options: Cheek plates: Mn13Cr2. Jaw plates: Mn13Cr2, Mn18Cr2, Mn22Cr2.

Voir plus

Stone Crusher,Concrete Plant,Washing Screening Plants

Mine Crushing, Screening, Washing Technologies and Concrete Plants GENERAL MAKINA. GENERAL MAKINA, founded in 1976 in Izmir / Turkey, is mainly in the Middle East and the Balkans; it manufactures Crushing and screening plants in all over the world. ... Producing a modern Stone Crusher Plant,Concrete Batching Plant, Crushing, Screening and ...

Voir plus

Breaking Ground and Barriers: The Evolution of Crushers in Mining

2023.9.11 Jaw Crusher - The Workhorse of Mining . Known for their simplicity and robustness, jaw crushers are the go-to choice for most primary crushing applications. These crushers use a pair of jaws to ...

Voir plus

China ZheJiang Tonghui Mining Crusher Machinery Co., Ltd.

Tonghui have 4 subsidiaries as follows, Tonghui Machinery, Tonghui Foundry, the Third Machinery Factory and Sanya Lingshui Changxing Quarry. Total production area covers 12000m 2. Annual production turnover reaches to RMB 100 million (USD 14.7 million). Tonghui is specialized in producing complete plant of mining crushing and screening

Voir plus

Stone Crusher Machine, Mobile Crusher Plant, Stone

2024.7.2 Henan Ascend Machinery Equipment Co., Ltd.(Pingdingshan Xingyang Resource Recycling Co.LTD) was established in 2005 and it is located in the high-tech zone of Zhengzhou City, Henan Province. As a technology driven mining equipment company, it is committed to the RD, production, sales and after-sales service of mining

Voir plus

Entretien Du Broyeur Crusher Mills, Cone Crusher, Jaw

Entretien: Rabe se lance dans le broyeur – Nouveautés – La Entretien Rabe se lance dans le broyeur. Publié le mercredi 18 avril 2007 – 18h05. Tweeter; Rabe prend place sur le marché du broyage avec son Chopper.

Voir plus

Mining Crusher Manufacturers Suppliers in India

Popular in Mining Crusher. Jaw Crusher Mining Crushing Machines, For Stone. ₹ 1.60 Lakh / Unit. Star Trace India. Contact Supplier. MRB Mild Steel Primary Stone Crusher Mining Machine, Capacity: 225 Tph. ₹ 15 Lakh / Piece. MRB Engineering Works. Contact Supplier.

Voir plus

>> Next:Vsi Beton De Prestations De Concasseur

Consulter en ligne

- application de plante de concassage de crusherplant de mâchoire

- concasseur mobile dolomite de c ne pour la location au nigeria

- broyeur de gestion de la machine

- porcelaine de cimenterie

- équipements sable maker

- annonce pour concassage de pierre Algérie

- pour concasseurs de roche shree

- ciment manuel de convoyeur telechargement gratuit

- machinary pierre concasseur en inde concasseurs

- broyeurs utilises dans les usines de fer amenagement de lusine

- Traitement du minerai d'or et de nickel

- location de plantes de concasseur à

- seule liste de prix de concasseur à machoires toogle

- broyeur de pierre vente broyeur ukstone vente usa

- la fabricación de cemento planta produciton línea de